COMCO Plastics, Inc. has been committed to innovation since 1956, pioneering the early use of thermosets and thermoplastics like nylon, phenolics, and Plexiglas™ in fabrication processes. Today, nearly seven decades later, we deliver reliable, precision-machined components to clients in diverse industries worldwide by utilizing high-quality plastics. Two of our extensive material options, Ultem® and PEEK,…

How to Polish Clear Plastic

COMCO is a pioneer in thermoplastic and thermoset fabrication, with over 50 years of experience. We deliver top-quality precision-machined and fabricated high-performance plastics for a multitude of industries. An ever-growing number of products and components are made from plastic materials. When used in demanding environments, clear plastics benefit from periodic polishing to enhance and restore…

What Is Vespel® and How Do You Use It?

Since 1956, COMCO Plastics, Inc., has been a trusted fabricator of high-quality plastic components. Our team has pioneered the use of innovative new plastics for over 65 years, including phenolics, nylon, thermosets, and thermoplastic materials. COMCO has grown alongside the plastics industry, and today, Vespel® is one of the many plastics that our team is…

Top 3 Reasons to Choose COMCO Plastics for Plastic Fabrication

Plastic fabrication entails designing, producing, and assembling components using techniques like molding, machining, and welding, among others. Achieving high-quality plastic products requires an experienced, reputable plastic fabricator, so it’s important to work with a partner you can trust. For over 60 years, COMCO Plastics, Inc. has maintained a reputation as a leading provider of plastic…

What Is Plastic Fabrication?

Plastic fabrication involves designing, manufacturing, and/or assembling plastic parts through a variety of methods, such as machining, compounding, molding, welding, and more. COMCO Plastics is a plastic fabrication specialist that works with a wide range of plastic materials, from Torlon® to ABS to nylon to PTFE. Our main capabilities are vacuum forming, CNC milling and…

How Does Vacuum Forming Work?

Vacuum forming is a valuable plastic product manufacturing method due to its cost-effectiveness and efficiency. This process generates components in various configurations and quantities while maintaining cost-effectiveness. Some of the many benefits of vacuum-forming plastic components include lower tooling costs compared to other manufacturing methods, faster prototyping, and lower costs per part for low to…

Temperatures for Thermoforming Polycarbonate

Polycarbonates are a group of thermoplastic polymers that are easily moldable, have high impact and temperature resistance, and are highly transparent to visible light. Thermoforming polycarbonate has numerous applications and can be used by many industries, including automotive, aerospace and aviation, building and construction, and medical equipment. Thermoforming Polycarbonate Thermoforming polycarbonate is a manufacturing process…

PTFE vs. Teflon®

PTFE and Teflon® are common thermoplastic materials used in various applications. Both terms reference the same material but one is its shortened chemical name and the other is its patented trade name. Continue reading to learn more about the features, advantages, and disadvantages of PTFE and Teflon®. What Is the Difference Between PTFE and Teflon®?…

Extruded vs. Cast Acrylic

Acrylic is a durable, transparent synthetic polymer that is produced through a chemical reaction between a monomer and a catalyst. Acrylic is an excellent alternative to glass due to its lightweight and enhanced transparency. Acrylic products can be manufactured using either casting or extrusion processes. Both methods offer unique advantages and disadvantages relative to the…

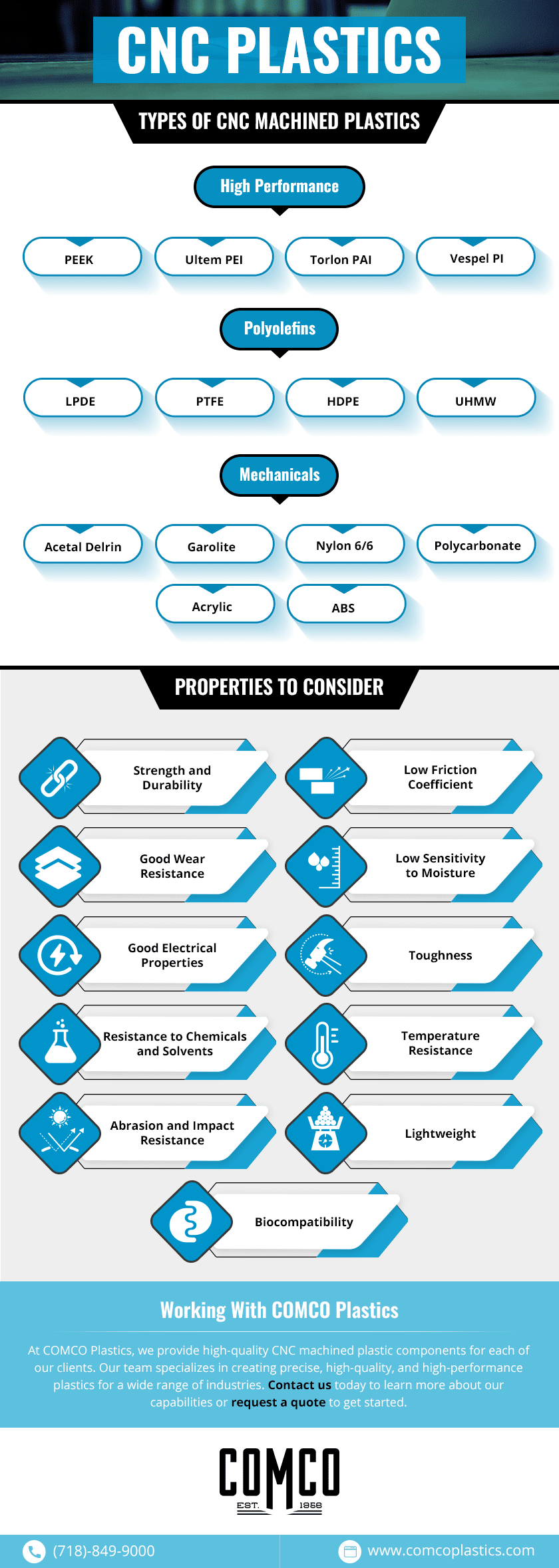

CNC Plastics: A Selection Guide

CNC manufacturing processes are increasingly popular due to their ability to produce high-quality, precision products with little human intervention. At COMCO Plastics, we specialize in CNC plastic manufacturing, including CNC milling and turning. We use multi-axis lathes and Swiss screw machines to create reliable, high-performance parts from a wide range of plastic materials. Each material…