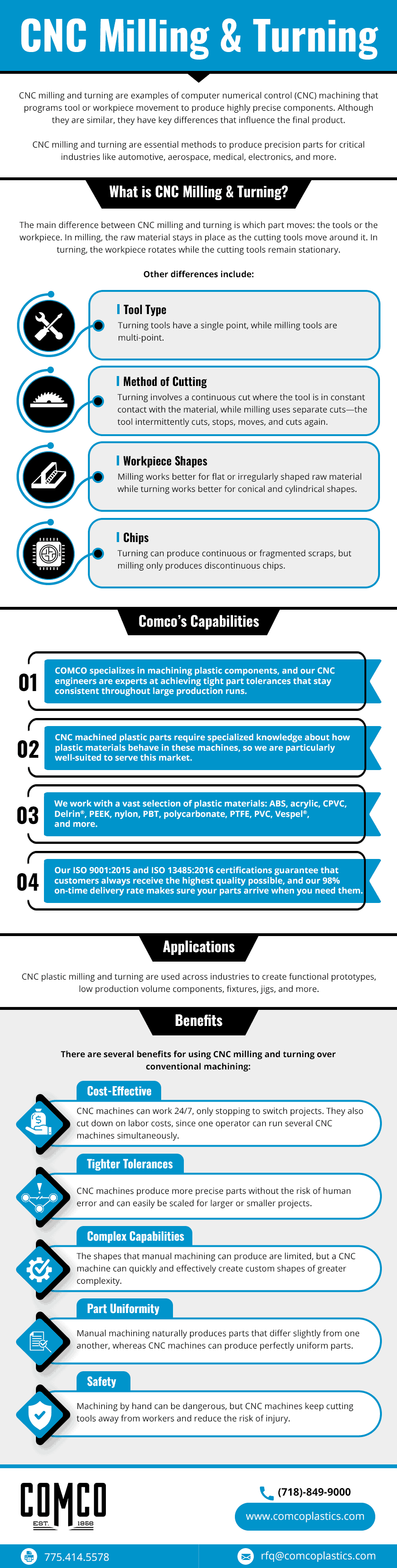

CNC milling and turning are examples of computer numerical control (CNC) machining that programs tool or workpiece movement to produce highly precise components. Although they are similar, they have key differences that influence the final product.

CNC milling and turning are essential methods to produce precision parts for critical industries like automotive, aerospace, medical, electronics, and more. This guide will discuss the features, applications, and benefits of milling and turning, as well as how COMCO Plastics can help you with your next project.

What Is CNC Milling & Turning?

The main difference between CNC milling and turning is which part moves: the tools or the workpiece. In milling, the raw material stays in place as the cutting tools move around it. In turning, the workpiece rotates while the cutting tools remain stationary. Other differences include:

- Tool type: Turning tools have a single point, while milling tools are multi-point.

- Method of cutting: Turning involves a continuous cut where the tool is in constant contact with the material, while milling uses separate cuts—the tool intermittently cuts, stops, moves, and cuts again.

- Workpiece shapes: Milling works better for flat or irregularly shaped raw material while turning works better for conical and cylindrical shapes.

- Chips: Turning can produce continuous or fragmented scraps, but milling only produces discontinuous chips.

COMCO’s Capabilities

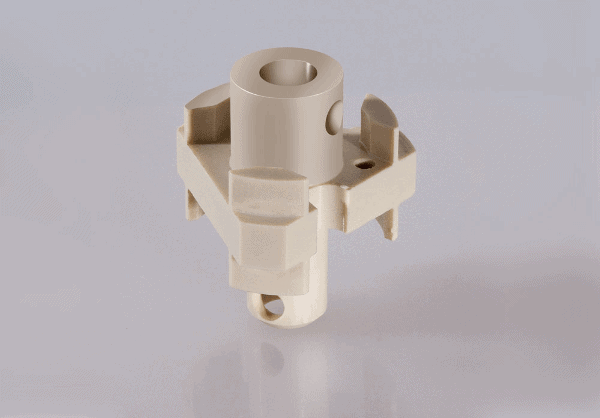

COMCO specializes in machining plastic components, and our CNC engineers are experts at achieving tight part tolerances that stay consistent throughout large production runs. CNC machined plastic parts require specialized knowledge about how plastic materials behave in these machines, so we are particularly well-suited to serve this market. We can handle any job, from simple to complex part geometries, and short to long production runs.

We work with a vast selection of plastic materials: ABS, acrylic, CPVC, Delrin®, PEEK, nylon, PBT, polycarbonate, PTFE, PVC, Vespel®, and more.

Our ISO 9001:2015 and ISO 13485:2016 certifications guarantee that customers always receive the highest quality possible, and our 98% on-time delivery rate makes sure your parts arrive when you need them.

Applications

CNC plastic milling and turning are used across industries to create functional prototypes, low production volume components, fixtures, jigs, and more.

Benefits of CNC Milling & Turning

There are several benefits for using CNC milling and turning over conventional machining:

- Cost-effective: CNC machines can work 24/7, only stopping to switch projects. They also cut down on labor costs, since one operator can run several CNC machines simultaneously.

- Tighter tolerances: CNC machines produce more precise parts without the risk of human error and can easily be scaled for larger or smaller projects.

- Complex capabilities: The shapes that manual machining can produce are limited, but a CNC machine can quickly and effectively create custom shapes of greater complexity.

- Part uniformity: Manual machining naturally produces parts that differ slightly from one another, whereas CNC machines can produce perfectly uniform parts.

- Safety: Machining by hand can be dangerous, but CNC machines keep cutting tools away from workers and reduce the risk of injury.

Plastic CNC Milling & Turning from COMCO Plastics

As experts in plastic CNC machining, COMCO Plastics can provide a level of expertise and quality you won’t get from typical metal machining companies. COMCO Plastics uses water-based coolants whereas a lot of metal machining companies use oil-based coolants. The benefit of using water-based coolant is that it’s easier to clean resulting in pristine components. Our capabilities include CNC milling and turning, annealing, assembly and fabrication, vapor polishing, vacuum forming, and more. We can deliver standard and custom solutions for your project on time, every time. Contact us or request a free quote for more information.