Plastic fabrication involves designing, manufacturing, and/or assembling plastic parts through a variety of methods, such as machining, compounding, molding, welding, and more. COMCO Plastics is a plastic fabrication specialist that works with a wide range of plastic materials, from Torlon® to ABS to nylon to PTFE. Our main capabilities are vacuum forming, CNC milling and turning, Swiss screw machining, annealing, vapor polishing, assembly, and quality inspection.

Understanding the various plastic fabrication methods and their benefits will help you determine the ideal method for your product.

Plastic Fabrication

Plastic fabrication includes the design, manufacture, and assembly of a product comprising plastic or composite materials. Modern plastic fabrication consists of various methods depending on the desired end product, and each method offers certain advantages and disadvantages. The process begins when a plastic fabrication company receives a request from a company or individual wanting to bring their product designs to life.

Plastic Fabrication Methods

The following plastic fabrication methods are most commonly used to make plastic products:

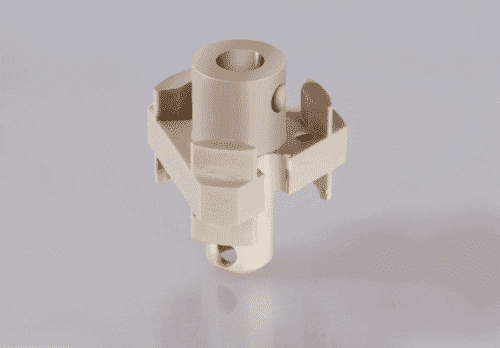

- Plastic machining: This popular plastic fabrication method relies on CNC turning, milling, and other machining processes. The automated tool cuts the plastic workpiece to the design specifications, able to create intricate details and tight tolerances.

- Plastic welding: Plastic welding involves joining two or more separate plastic workpieces by applying heat and pressure. Variants include contact welding, speed tip welding, and hot gas welding.

- Thermoforming: Thermoforming heats a plastic sheet until pliable and forms it by stretching it over a mold using a vacuum and trimming the edges. We can use thermoforming for small and large production volumes.

- Blow molding: There are three main types of blow molding: injection stretch blow molding, injection blow molding, and extrusion blow molding. Pressurized air travels into a molten thermoplastic tube, expanding the plastic until it fills the mold.

- Fused deposition modeling: This plastic fabrication method relies on a 3D printer to build a plastic model in continuous 2D layers. The printer uses an automated printhead nozzle to disperse the plastic. It is fast and cost-effective and works with various plastics, including PEEK, PLA, and ABS.

- Injection molding: Injection molding is the prevalent fabrication method for thermoset polymers and thermoplastics. Plastic pellets are heated, injected into a mold as a liquified material, and cooled to solidify in the shape of the mold.

- Plastic extrusion: Plastic is heated in a barrel, forced through a die using a screw, and allowed to harden as it cools. The method provides a continuous profile and can be used for large volumes of parts.

- Rotational molding: This is a fabrication method that uses a rotating mold to evenly distribute molten plastic throughout the mold cavity. The process is slow but provides uniform wall thicknesses and strong corners.

- Stereolithography: This fabrication method relies on a photopolymeric resin 3D printer, curing resin layers with UV light.

The products are smooth and intricate but more brittle than those created via other methods.

Benefits of Plastic Fabrication

Working with a reliable plastic fabrication provider to manufacture your plastic parts provides the following benefits:

- Enhanced strength: Plastics can be formulated to have a higher strength-to-weight ratio than other materials and high stiffness even when exposed to heat.

- Material and color flexibility: Plastics come in many colors, and fabrication methods are compatible with various plastic materials. We can adapt our techniques and materials to facilitate the desired results.

- Fast production and improved efficiency: Compared to metal fabrication, plastic fabrication offers quicker production cycles and enhanced efficiency for your operation.

- Low costs: Plastic fabrication products can be manufactured in low to high volumes with automated efficiency and little supervision.

- Reduced waste: A quality plastic fabrication company has systems in place to recycle the excess plastic that results from various fabrication methods. Plastic fabrication also reduces material waste by reducing the likelihood of human error.

Why Choose COMCO Plastics

Plastic fabrication is the design, assembly, and manufacturing of plastic parts and products. Plastic fabricators employ different techniques depending on the needs of various applications. When done right, plastic fabrication provides many benefits to customers and end-users alike.

COMCO Plastics has been recognized worldwide for fabricating precision-machined, high-performance plastics for various industries since 1956. We were among the first to work with thermoplastics and thermosets such as nylon, phenolics, and Plexiglas® before they became used more widely by other manufacturers. COMCO has promoted the plastics industry’s growth and continues to be a leader.

Contact us or request a quote to learn more about our plastic fabrication capabilities.