Plastic is a highly regarded material in the world of modern industry as it’s an essential resource for manufacturing anything from everyday household and commercial items to critical industrial parts. Its biological, chemical, and mechanical properties make it an optimal choice for various engineering applications in industries across the globe.

One way to create precision plastic components for the aerospace, automotive, and electronics sectors and beyond is plastic machining. This subtractive machining process removes material from the plastic raw stock to generate a finished product of a prespecified shape and size. This fabrication method actually covers many different machining processes and incorporates equipment like cutting machinery, drill presses, grinders, lathes, mills, and other such tools. Computer numerical control (CNC) machining is a common manufacturing process.

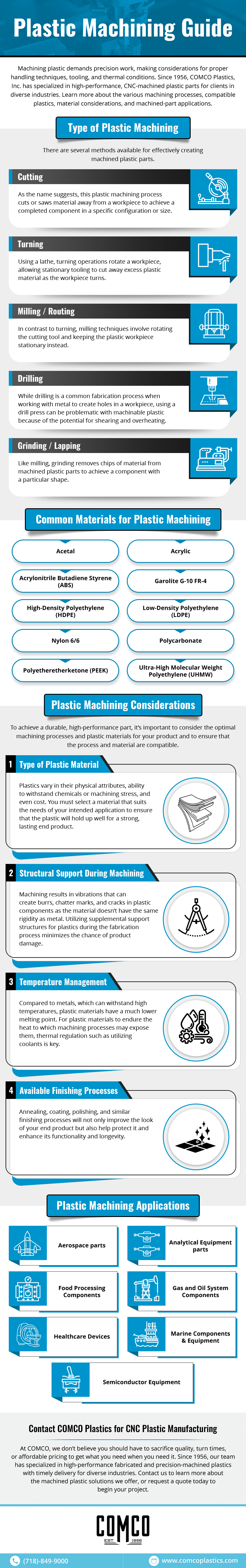

Machining plastic demands precision work, making considerations for proper handling techniques, tooling, and thermal conditions. Since 1958, COMCO Plastics, Inc. has specialized in high-performance, CNC-machined plastic parts for clients in diverse industries. Learn more about the various machining processes, compatible plastics, material considerations, and machined-part applications.

Type of Plastic Machining

There are several methods available for effectively creating machined plastic parts.

Cutting

As the name suggests, this plastic machining process cuts or saws material away from a workpiece to achieve a completed component in a specific configuration or size. One thing to note is that, when using cutting techniques on machinable plastics, operators must exercise extreme care to prevent thermal warping as a result of the heat that the manufacturing process produces.

Turning

Using a lathe, turning operations rotate a workpiece, allowing stationary tooling to cut away excess plastic material as the workpiece turns. This ultimately creates machined plastic parts that are symmetrical based on the rotation axis.

Milling / Routing

In contrast to turning, milling techniques involve rotating the cutting tool and keeping the plastic workpiece stationary instead. The method effectively removes plastic chips from the workpiece. Down-milling is one of the preferred options when machining plastic specifically.

Drilling

While drilling is a common fabrication process when working with metal to create holes in a workpiece, using a drill press can be problematic with machinable plastic because of the potential for shearing and overheating. With the proper drill, however, skilled operators can generate holes of varying diameters in plastics without causing damage.

Grinding / Lapping

Like milling, grinding removes chips of material from machined plastic parts to achieve a component with a particular shape. Instead of using intermittent cuts, however, grinding or lapping is a continuous process that shears excess material from the workpiece for a smoother finish on a part’s surface.

Common Materials for Plastic Machining

Machined plastic has a lower thermal resistance than metal, which can present a significant challenge during machining operations. Overheating, warping, thermal expansion, and general thermal damage are common problems that manufacturers experience during the fabrication process. Despite thermal considerations in machining plastic components, when using the right material and tools, plastic materials can create superior machined parts.

Depending on the material, plastics can offer excellent strength-to-weight ratios, insulating properties, and varied resistance capabilities to generate durable industrial, commercial, and consumer products. The trick is to match your material to your application’s needs. Common materials for plastic machining include:

- Acetal. An optimal plastic for complex applications, high-precision work, or mechanical parts like gears and bearings, acetal is a high-strength material with beneficial mechanical characteristics. It also offers temperature resistance, which is essential when creating machined plastic parts.

- Acrylic. This lightweight, impact-resistant thermoplastic lends a superior optical quality to machined plastic parts and doesn’t discolor from extended exposure to UV rays. One drawback is that acrylic isn’t resistant to high temperatures. This plastic material can replace glass in piping applications.

- Acrylonitrile Butadiene Styrene (ABS). A plastic with good machinability and superior mechanical characteristics, ABS is a cost-effective and popular option for machined plastic components. It can handle diverse applications for industries ranging from automotive to consumer products. CNC-machined parts of ABS material construction are rigid and tough, with optimal shock absorbency capabilities.

- Garolite G-10 FR-4. The characteristics of this glass-reinforced epoxy composite make it a popular option for electronic and marine applications. The material offers corrosion, fire, and moisture resistance; a high strength-to-weight ratio; and optimal electrical insulation.

- High-Density Polyethylene (HDPE). HDPE has a high strength-to-weight ratio in CNC-machined parts. With chemical- and moisture-resistant properties, HDPE is an optimal solution for applications requiring durable, lightweight materials, making it an optimal choice for packaging applications. The material is also a preferred choice when manufacturing machined plastic parts for the automotive, construction, and electrical industries.

- Low-Density Polyethylene (LDPE). This rugged plastic is a corrosion- and chemical-resistant material. Featuring flexibility at low temperatures, LDPE lends itself to ideal applications in products that benefit from good flex, which can range from containers to prosthetics. For this same reason, however, it’s not intended for applications that need a material with stiffness or high strength and temperature resistance. LDPE is simple to weld and heat seal for good machinability.

- Nylon 6/6. A popular plastic that’s often an alternative material for metal, nylon 6/6 provides good toughness and hardness properties and has good abrasion, chemical, and thermal resistance. Nylon 6/6 is an ideal option for machining mechanical components for load-bearing applications. The high-performance material is also cost-effective in CNC machining operations.

- Polycarbonate. This lightweight plastic material offers excellent fracture toughness, optical clarity, and resistance to impact damage, UV rays, and high temperatures. Polycarbonate is ideal for anything from structural components and pipes to safety glasses and optical disks.

- Polyetheretherketone (PEEK). The beneficial properties of PEEK include biocompatibility, high-temperature resilience, and resistance to abrasion, chemicals, and ultra-high vacuum. The material can maintain its performance in temperatures as high as 260º C and is a good choice for applications in the aerospace, automotive, and healthcare sectors requiring CNC-machined plastic parts.

- Ultra-High Molecular Weight Polyethylene (UHMW). A highly machinable option, UHMW is versatile, durable, and resistant to chemicals, general wear, and abrasion. UHMW has low-friction properties that make it an appealing choice for automotive applications, food and beverage processing equipment, fender pads for marine docks, wear strips, and much more.

Plastic Machining Considerations

To achieve a durable, high-performance part, it’s important to consider the optimal machining processes and plastic materials for your product and to ensure that the process and material are compatible.

Type of Plastic Material

Plastics vary in their physical attributes, ability to withstand chemicals or machining stress, and even cost. You must select a material that suits the needs of your intended application to ensure that the plastic will hold up well for a strong, lasting end product.

Structural Support During Machining

Machining results in vibrations that can create burrs, chatter marks, and cracks in plastic components as the material doesn’t have the same rigidity as metal. Utilizing supplemental support structures for plastics during the fabrication process minimizes the chance of product damage.

Temperature Management

Compared to metals, which can withstand high temperatures, plastic materials have a much lower melting point. For plastic materials to endure the heat to which machining processes may expose them, thermal regulation such as utilizing coolants is key.

Available Finishing Processes

Annealing, coating, polishing, and similar finishing processes will not only improve the look of your end product but also help protect it and enhance its functionality and longevity.

Plastic Machining Applications

Numerous industries have applications for machined plastic parts. The process is well-suited for creating:

- Aerospace parts

- Analytical equipment parts

- Food processing components

- Gas and oil system components

- Healthcare devices

- Marine components and equipment

- Semiconductor equipment

Contact COMCO Plastics for CNC Plastic Manufacturing

At COMCO, we don’t believe you should have to sacrifice quality, turn times, or affordable pricing to get what you need when you need it. Since 1956, our team has specialized in high-performance fabricated and precision-machined plastics with timely delivery for diverse industries. Contact us to learn more about the machined plastic solutions we offer, or request a quote today to begin your project.