CNC manufacturing processes are increasingly popular due to their ability to produce high-quality, precision products with little human intervention. At COMCO Plastics, we specialize in CNC plastic manufacturing, including CNC milling and turning. We use multi-axis lathes and Swiss screw machines to create reliable, high-performance parts from a wide range of plastic materials. Each material offers its own unique properties that make it suitable for various applications.

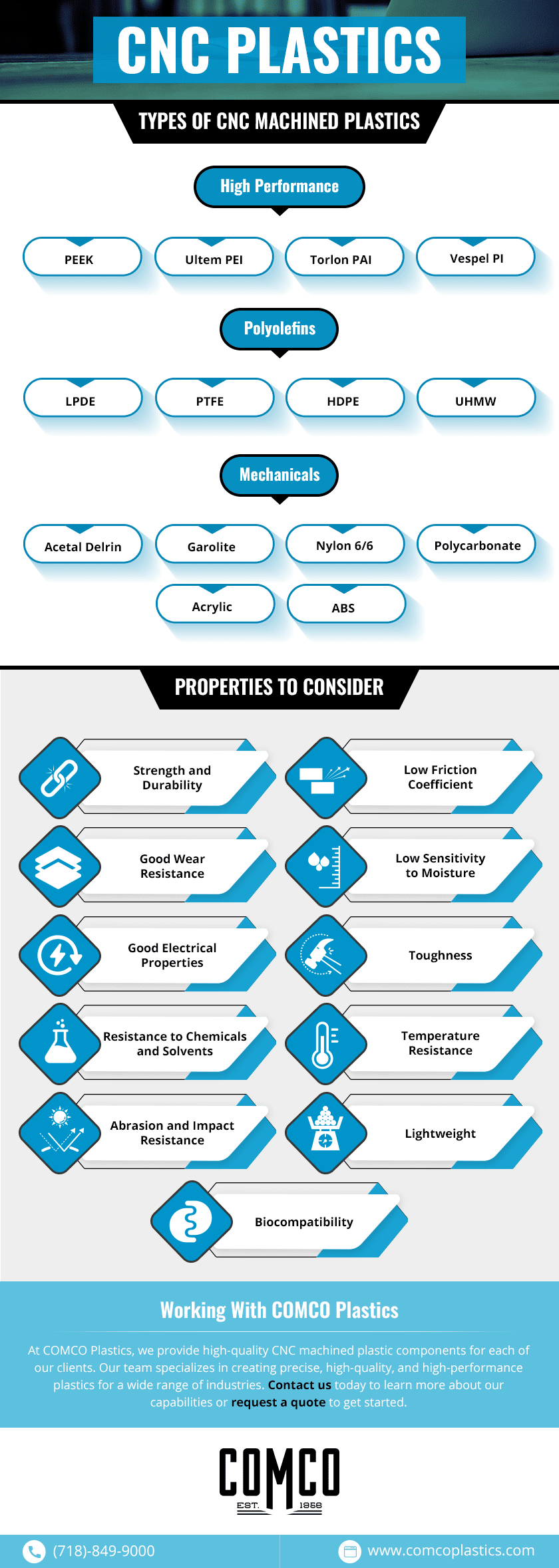

Types of CNC Machined Plastics

Manufacturers use a wide variety of different plastic polymers and materials to create consumer, commercial, and industrial goods. Every material has different properties that make it an ideal fit for specific end uses. Some materials are more suited for CNC machining than others, so it’s important to have a strong understanding of the various materials and their capabilities. You can view COMCO Plstic’s materials by visiting here. Some of the most popular types of CNC machined plastics include:

Acetal

This high-strength plastic is very dimensionally stable, has great mechanical properties, and is temperature resistant. This makes it a popular choice for complex machining projects that require extreme precision. Acetal is often used to machine mechanical components such as bearings and gears.

Acrylic

This thermoplastic material is light, resists impact damage, and does not discolor due to prolonged UV exposure. This gives machined goods excellent optical quality. However, acrylic materials shouldn’t be exposed to high temperatures. It is commonly used as an alternative to glass for piping applications.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a cost-effective material that features good manufacturability and excellent mechanical properties, making it a popular material across various industries. CNC machined ABS exhibits shock absorbency, rigidity, and remarkable toughness. This material is popular in the automotive industry as well as various consumer products.

Garolite G-10 FR-4

This glass-reinforced epoxy composite features great moisture and corrosion resistance, a high strength-to-weight ratio, fire resistance, and electrical insulative properties. These characteristics make it a popular choice for machined parts used in marine and electronics applications.

High-Density Polyethylene Plastics (HDPE)

CNC machined HDPE exhibits good moisture and chemical resistance and a high strength-to-weight ratio. This engineering plastic material is ideal for applications requiring low weight and high strength. It is used extensively in the packaging industry as well as for creating components for the automotive, electrical, and construction industries.

Low-Density Polyethylene (LDPE)

This material is tough, resistant to corrosion, and features low-temperature flexibility, making it a great choice for items like prosthetics and containers that need flex. This material is easy to heat seal and weld and also offers good resistance to chemicals. However, LDPE should not be used for applications that require high structural strength, high-temperature resistance, and stiffness.

Nylon 6/6

Nylon 6/6 is a popular material that features great hardness, toughness, and resistance to chemicals, temperatures, and abrasion. These characteristics make it suitable for load-bearing mechanical components, and it is often used as an alternative to metal. CNC machining Nylon 6/6 results in high-performance and cost-effective components that exhibit excellent mechanical and thermal properties.

Polycarbonate

Compared to other engineering plastics, polycarbonate offers great impact resistance, exceptional fracture toughness, UV and high-temperature resistance, and optical clarity. This lightweight material is ideal for optical disks, pipes, safety glasses, and various structural components.

Polyetheretherketone (PEEK)

PEEK offers several beneficial properties, including exceptional chemical resistance, biocompatibility, abrasion resistance, resilience at high temperatures, and resistance to ultra-high vacuum. It can operate at temperatures up to 260°C, and common applications include CNC machined components for the automotive, aerospace, and medical industries.

Ultra-High Molecular Weight Polyethylene (UHMW)

UHMW is a highly machinable plastic material that is tough, versatile, and resistant to abrasion, wear, and chemicals. This material is ideal for applications requiring a low-friction and durable plastic. UHMW is commonly used in the food & beverage, marine, and automotive industries for components such as wear strips, food processing machinery, marine dock fender pads, and more.

Properties

Different plastics have different properties that can impact their ability to perform in different applications. It’s important to consider the specific needs of your application and industry when selecting the proper material for your needs. Doing so will ensure the chosen material’s properties line up with the requirements of your product. When choosing a CNC machining material, consider looking for materials that exhibit properties such as:

- Strength and durability

- Low friction coefficient

- Good wear resistance

- Low sensitivity to moisture

- Good electrical properties

- Toughness

- Resistance to chemicals and solvents

- Temperature resistance

- Abrasion and impact resistance

- Lightweight

- Biocompatibility

Applications

CNC machined components are used across a wide range of applications, including:

- Aerospace components

- Medical devices

- Oil and gas system components

- Analytical equipment components

- Construction equipment

- Marine equipment

- Food processing

CNC machined plastic parts are also used throughout the semiconductor industry due to their many beneficial properties. Parts used in semiconductor manufacturing require extreme precision and quality, making CNC machined plastic components an ideal choice.

Contact COMCO Plastics for CNC Plastic Manufacturing

At COMCO Plastics, we provide high-quality CNC machined plastic components for each of our clients. Our team specializes in creating precise, high-quality, and high-performance plastics for a wide range of industries. Contact us today to learn more about our capabilities or request a quote to get started.