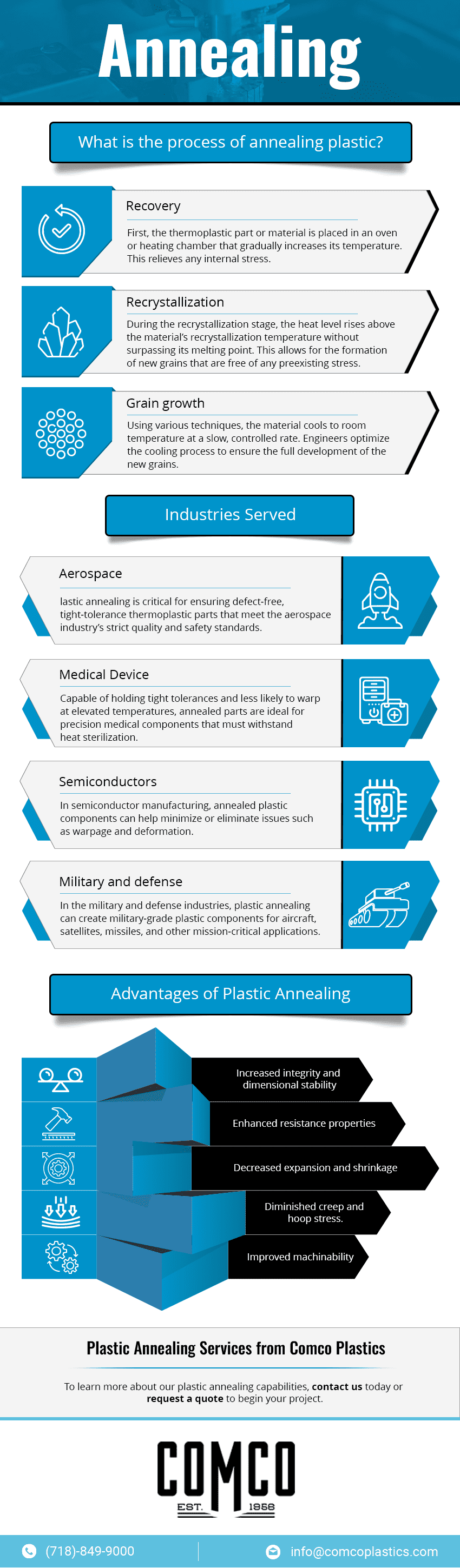

Types of Annealing

Annealing plastic is achievable through several methods. Some of the most common annealing processes for plastic include:

- Oil annealing. This process utilizes an oil bath to anneal engineering plastic components. Although oil annealing was once considered the most effective heat treatment process, it can be costly to run and maintain. This method also necessitates further machining of the oil-stained material before the parts can go to market. While oil annealing is still prevalent in Europe, OSHA and the EPA have made it illegal to perform in the U.S.

- Air annealing. Sometimes called browning, air annealing involves placing the workpiece in a nitrogen atmosphere to reduce the risk of surface oxidation. This process uses both added pressure and a free state, and it is the most common method seen in most American mills today.

- Inline annealing. This annealing method is used to anneal extruded plastic materials quickly after extrusion. By doing so, the annealing process is optimized by leveraging the residual heat in the material from extrusion. During the inline annealing process, the workpiece goes through a slow cooling zone while heaters in-line with extruders add calories. While this process may not be as effective as air annealing, it offers faster speeds and lower costs.

When you work with COMCO Plastics, we offer a custom consultative approach that allows you to work through the OEM instead of with a machine shop to ensure your plastic components meet your specifications. We can work with you to help you determine which annealing method is the right fit for your needs.

What Plastics Are Commonly Used in Annealed?

Thermoplastic parts and components are produced using a wide variety of processes that can introduce stress into the materials. Annealing is used to reduce this stress while also increasing the material’s hardness and strength. During the annealing process, the plastic material is heated to just below its glass transition temperature before it is cooled. This should be performed relatively slowly to prevent shocking the plastic, which could otherwise lead to instability.

The annealing process is commonly used to treat various thermoplastic parts, including those made with:

- Acrylic

- Polycarbonate

- Nylon

- LDPE

- HDPE

- Polyurethane

- And more

COMCO Plastics’ experience in annealing ensures we choose the right material for your project from the start.

Annealing Plastics

If a large amount of plastic material is removed during the machining process, annealing can relieve stress and reduce the likelihood of premature part failure. When trying to achieve optimal part flatness, you can machine the part to its near-final shape and then anneal it to relieve the stress, ensuring the part will stay flat.

During the plastic extrusion process, the plastic stock material is compressed through a profile die. The high amount of compression can introduce stress into the material that can lead to a variety of problems if not addressed. These issues include:

- Warping and distortion

- Lower physical properties

- Higher risk of cracking

- Final part dimensions may change

To eliminate these issues, it is important to anneal extruded plastic products. By exposing it to heat just below its glass transition temperature, the plastic part can decompress into a relaxed state. Annealing is an important step to take if you want a high-quality finished product.

When Is Annealing Required and Why Is it Important?

Annealing is a crucial process because it can reverse the effects of work hardening caused by processes such as drawing, bending, and cold forming. If plastic materials become too hard, they have a higher possibility of cracking and become more difficult to work with. By heating the material above its recrystallization temperature, internal stress is relieved and the material’s ductility increases, making it workable again.

Plastic Annealing Services From COMCO Plastics

Plastic annealing plays an important role in improving the machinability of plastics and creating higher-quality parts that are less susceptible to mechanical and chemical stresses. For optimal results, it is important to work with an experienced provider who can correctly adjust each annealing variable according to the material’s specific properties.

COMCO Plastics is a one-stop-shop plastics manufacturer specializing in the production of precision-machined high-performance plastics and components. As a value-added service, our plastic annealing capabilities allow us to optimize the plastic parts we produce for a range of harsh, high-stress environments. With our goal of continuous improvement and innovation, we work hard to ensure on-time, affordable, high-quality products that we manufacture to your exact specifications to best fulfill the needs of your application.

To learn more about our plastic annealing capabilities, contact us today or request a quote to begin your project.