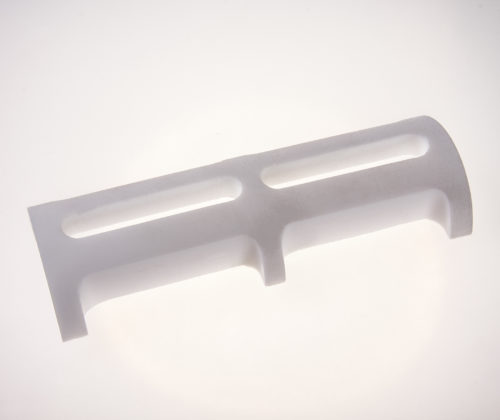

Teflon® is a soft, low friction material that sees extensive use across a range of applications due to its resistant and insulating properties. As a leading manufacturer of high-performance plastics, COMCO Plastics can deliver a range of high-quality, precision Teflon® components to meet various industry needs.

What is PTFE/Teflon®?

Polytetrafluoroethylene (PTFE), or Teflon® as it is commonly known, is a synthetic tetrafluoroethylene fluoropolymer. Depending on the needs of a particular application, the mechanical properties of PTFE, such as creep and wear rate, can be improved with the addition of fillers. Ideal fillers include graphite, carbon fiber, carbon, steel, bronze, and glass fiber.

The specific properties of PTFE include:

- Low water absorption

- Availability of high-purity grades for food and medical applications

- Good fatigue resistance under low stress

- Highly flexible

- Strong anti-adhesion properties

- Low dielectric constant and dissipation factor

- Low coefficient of friction

- Good resistance to weathering, UV, and light

- Good electrical insulation properties in hot and wet environments

- Good heat and low-temperature resistance

- Exceptional resistance to chemicals

- PTFE/Teflon® Applications

Various applications rely on PTFE, including:

- Automotive: Power steering, transmission, fuel hose linings, shaft seals, valve stem seals, gaskets, and O-rings

- Chemical Industry: Containers, autoclaves, reaction vessels, tanks, impellers, diaphragms, pumps, and heat exchanger coatings

- Electrical and Electronics: Semiconductor parts, flexible printed circuit boards, electrical insulation

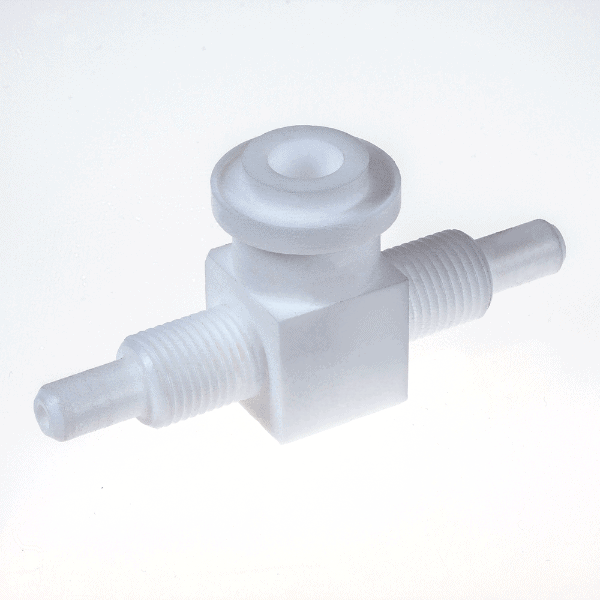

- Engineering: Pump and valve parts, fittings, pipe coatings, non-stick surfaces, bearings, seals, and plugs

- Medical: Heart patches, ligament replacement, and cardiovascular grafts

PTFE/Teflon® Machining Considerations

When machining Teflon®, it is vital to consider its characteristics to ensure you deliver the desired results. For example, consider the following:

- PTFE has a density and softness that makes it easy to machine

- PTFE has an extensive temperature range from -450 °F to more than 500 °F (-267.7 °C to +260 °C)

- Teflon®‘s strength is low compared to nylon

- Tight tolerances can be difficult to achieve due to PTFE’s sensitivity to stress creep and a high coefficient of expansion

- Joining PTFE can be difficult

- PTFE may release toxic fumes and has corrosive properties

- PTFE has a low resistance to radiation

Rely on COMCO Plastics for Your PTFE/Teflon® Machining Needs

PTFE is valued by many industries for its high resistance to chemicals, low coefficient of friction, electrical insulating properties, and resistance to heat, cold, UV, and weathering. When working with PTFE for your products, it’s important to partner with an experienced plastics manufacturer that understands the different benefits and drawbacks of the material and can deliver the ideal results.

COMCO Plastics relies on cutting-edge fabrication technology, and our facility allows us to deliver custom Teflon® parts with high precision to meet a range of industry and application requirements.

Our machining and fabrication capabilities include:

- CNC Milling and Turning

- Lathe and Swiss Screw

- Vacuum Forming

- Fabrication and Assembly

- Vapor Polishing

- Annealing

- Quality and Inspection

When you partner with COMCO Plastics for your fabrication project, you get quality, delivery, and price without compromise. Contact us to learn more about our capabilities, or request a quote on the PTFE fabrication services of your choice.