Our Capabilities

CNC Milling & Turning

CNC Milling & Turning

Some parts are more complicated tha…

Lathe & Swiss Screw

Lathe & Swiss Screw

Comco’s expertise in turning plas…

CNC Milling

CNC Milling

Some parts are more complicated tha…

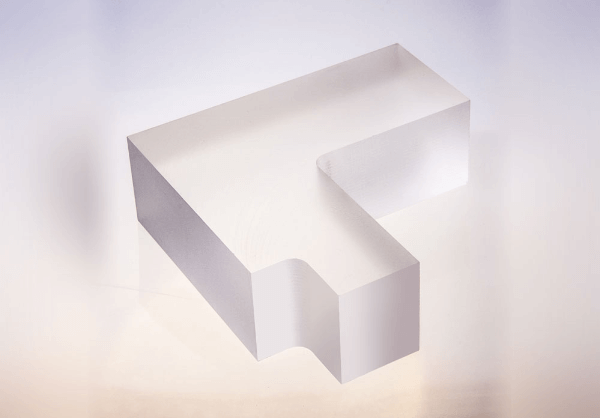

Vacuum Forming

Vacuum Forming

Our custom made Vacuum Forming Equ…

Assembly & Fabrication

Assembly & Fabrication

Our White Glove Fabrication Services…

Vapor Polishing

Vapor Polishing

When optical clarity is required, C…

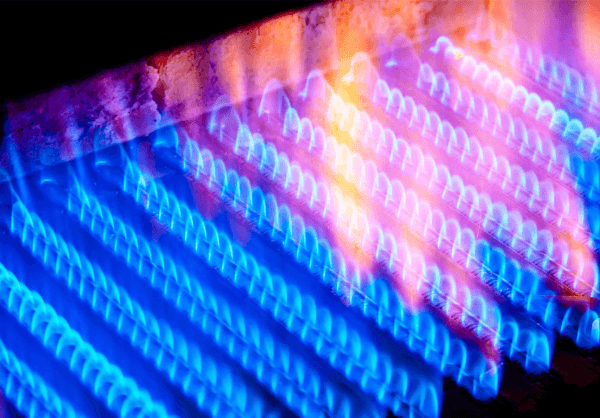

Annealing

Annealing

As Plastic Experts for 60 Years, Co…

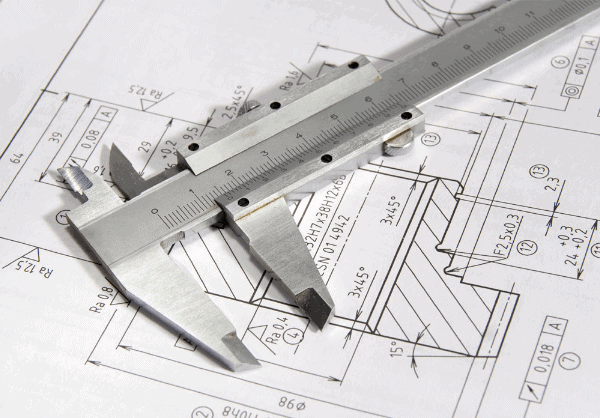

Quality & Inspection

Quality & Inspection

Beyond our ISO 9001 and ISO 13485 C…

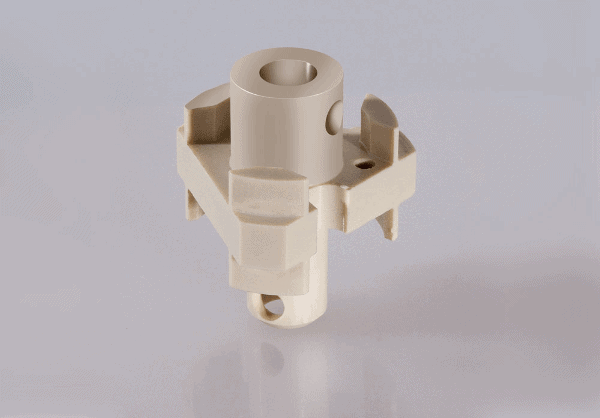

Medical Devices

Medical Devices

Medical device components mus..

Semiconductors

Semiconductors

The semiconductor industry re..