When producing plastic parts, manufacturers may use the vacuum forming process. Vacuum forming is a popular method of plastic product manufacturing because of its cost-effectiveness and efficiency. This process can produce components in a wide range of configurations of varying quantities while maintaining affordability. At COMCO Plastics, we manufacture a variety of high-performance plastic products using this method and our custom vacuum forming equipment.

What Is Vacuum Forming?

Vacuum forming is the most basic type of thermoforming, using a single mold and vacuum pressure to create a plastic component. Parts that only require one side with precision forming tend to rely on this process, such as contoured packaging for electronics and food items.

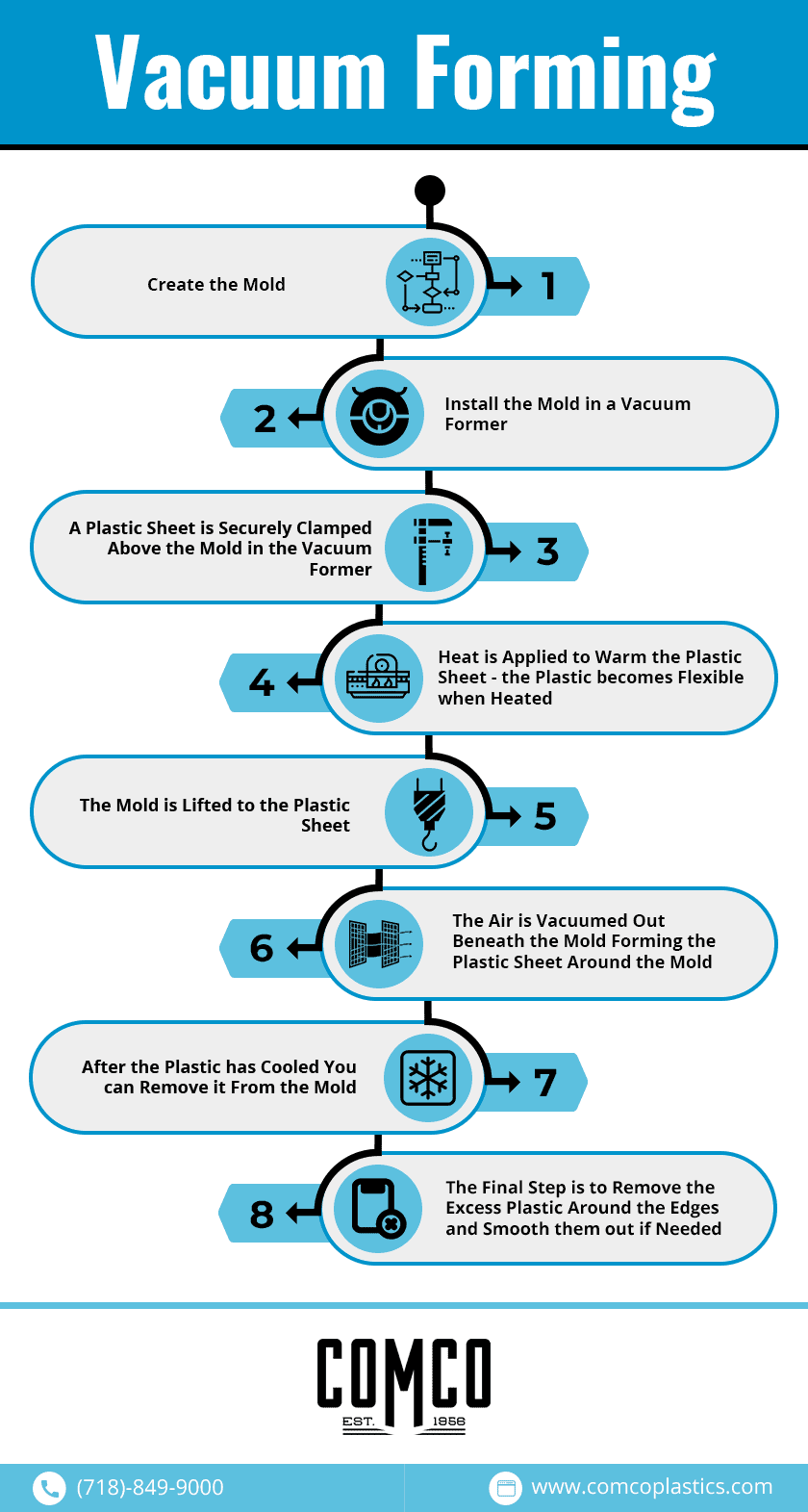

Vacuum forming works by heating plastic materials to a temperature that is high enough to enable a mold to change the shape of the material. To form the ideal shape, the process uses a vacuum in combination with heat. During this process, a vacuum pulls between the mold and the plastic sheet, creating an air pressure differential that forces the heated plastic material against and around the mold.

A variety of materials are compatible with plastic vacuum forming processes. Some of these materials include:

- Acrylic. A transparent and UV-resistant plastic, acrylic vacuum forming is useful in applications where optical clarity is important, like viewing ports and machinery enclosures.

- Acrylonitrile butadiene styrene (ABS). Often formulated to meet UL flammability standards, ABS plastic is commonly used in vacuum forming for its durability, given its resistance to impact.

- High-density polyethylene (HDPE). This cost-effective plastic has the benefit of high-impact strength even with exposure to chemicals or low-temperature environments.

- High-impact polystyrene (HIPS). Another affordable material, HIPS is highly formable, with applications including POP displays.

- Polycarbonate. This is a thermoplastic material with transparent, strong, and stiff properties and outstanding impact resistance.

- Thermoplastic polyolefins (TPO). This high-impact plastic is suitable for the automotive and industrial fields with many high- and low-temperature applications as well.

- Polyethylene terephthalate glycol (PETG). This thermoplastic polyester possesses greater strength than acrylic but less than polycarbonate and also provides significant chemical resistance, durability, and formability for manufacturing.

Applications

As a result of its cost-effectiveness and reliability, vacuum forming has many manufacturing applications in producing plastic parts, including applications requiring larger parts manufactured with automated equipment and small parts made with desktop devices. Some of these applications include:

- Agriculture. Tractor parts, feed containers, and animal housings are some of the many vacuum-formed agricultural products.

- Engine coverings. Useful in the construction sector, vacuum-formed plastics can function as machinery engine covers.

- Forklift cab enclosures. Often made of vinyl, vacuum-formed cab enclosures protect forklift operators from the elements.

- Industrial applications. Crates and other various industrial equipment containers use vacuum forming in their fabrication.

- Medical sector. Vacuum forming produces many medical products that require resistance to microbes and other contaminants.

- Protective shipping covers. Impact-resistant plastic can protect products during transport.

- Railcars. Vacuum forming can help in the creation of interior trim and seating parts.

- Safety guards. Vacuum-formed plastic helps protect equipment or products while still offering visibility when paired with transparent materials.

Vacuum Forming Capabilities From COMCO Plastics

Since the early 1960s, COMCO has led the industry as a pioneer of vacuum forming. If you require dependable vacuum forming services for plastic products, COMCO Plastics has the resources and capabilities needed to produce the best achievable results. Our custom vacuum forming equipment facilitates vacuum forming of materials up to .375 inches within a window of 40 x 47 inches and with a potential draw of as much as 18 inches.

High-Performance Plastics From COMCO Plastics

For applications requiring high-quality and cost-effective vacuum forming services, COMCO Plastics is here to give you what you need. In addition, our capabilities include CNC milling and turning, vapor polishing, assembly and fabrication, annealing, and quality and inspection.

To find out more about our materials and capabilities, contact us today. If you would like to get started on your next project with us, request a quote at any time.