Torlon is a high-performance plastic that offers resistance to elevated temperatures, stress, and creep. It also has excellent mechanical strength characteristics, making it a popular choice for applications across a range of industries.

What is Torlon®/PAI?

Torlon polyamide-imide (PAI) is a high-performance thermoplastic that offers the optimal combination of temperature resistance and melts processability. Its impact and abrasion resistance along with its ability to carry high loads over a wide range of temperatures make it a popular material choice for wear applications and structural components. Engineers around the world prefer Torlon over other thermoplastics and comparable metals because of its many favorable characteristics, including:

- Excellent wear and tribological performance

- High compression and tensile strength

- Excellent heat deflection temperature

- Great impact strength

- Good machinability

- Outstanding stiffness and strength at high temperatures

- Exceptional coefficient of thermal expansion

- Great thermal stability

- Resistance to chemical damage

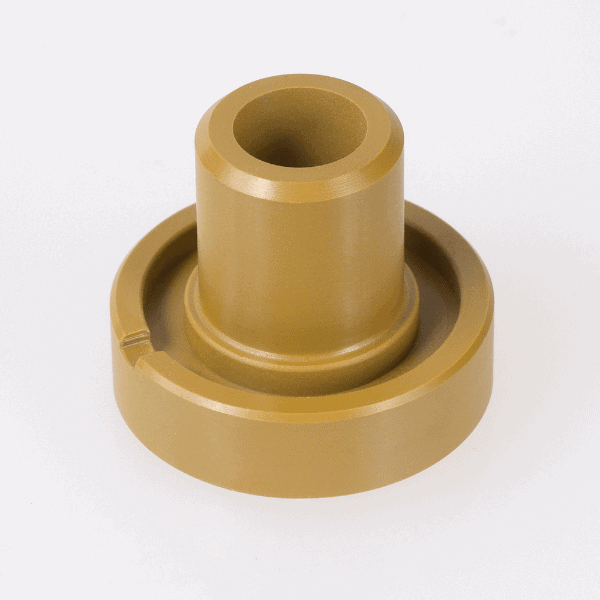

Torlon®/PAI Applications

Torlon material is used across multiple different markets and industries. Some of the most common applications for Torlon parts and components include:

- Natural gas compressor components

Electrical connectors

- Insulators

- Fasteners

- Labyrinth seals

- Linkages

- Nests

- Bearing components

- Pump parts and systems

- Sealing rings

- Sliding compressor vanes

- Sockets

- Test sockets

Torlon®/PAI Machining Considerations

Different materials often have various design, manufacturing, and end-use constraints that both product designers and manufacturing experts need to account for. Because of Torlon’s positive characteristics, manufacturers can work with the material to reliably produce complex and precise components. Some of the considerations for machining Torlon include:

- Low expansion coefficient. Torlon remains dimensionally stable throughout the machining process and won’t expand or contract unpredictably due to higher temperatures.

- Ease of use. Torlon is easy to fabricate and machine using various processes.

- Excellent strength characteristics. Torlon offers excellent fatigue, impact, and mechanical strength properties, making it ideal for extreme working conditions.

- Resistance to Damage. Torlon can resist damage from creep and wear and is also resistant to various chemicals, including acids, mild bases, gasoline, and more.

- Heat Resistance. Torlon can safely be used across a wide temperature range from cryogenic temperatures up to 500° F. It also has great thermal stability and low flammability and generates low levels of smoke.

- Customization Possibilities. Torlon can be combined with additives to enhance certain characteristics. For example, fabricators can add glass to the formula to increase the material’s load capacity.

Every project’s material needs are different. Work with an experienced manufacturing service that can help you determine if Torlon/PAI is the right fit for your project.

Turn to COMCO Plastics for Torlon®/PAI and More

At COMCO, we specialize in high-quality fabrication, machining, manufacturing, and finishing services. With our state-of-the-art fabrication facility and in-house manufacturing capabilities, we can produce standard and custom Torlon goods from start to finish. Our capabilities include:

- Fabrication

- CNC milling and turning

- Lathe and Swiss screw machining

- CNC milling

- Vacuum forming

- Assembly services

- Vapor polishing

- Annealing

- Complete quality and inspection services

We have been serving clients across multiple industries for over 65 years, providing precision parts that meet all of our customers’ material and application requirements. Contact us today to learn more about our in-house production capabilities, or request a quote to start your next project.

Electrical connectors

Electrical connectors